Process

Industries

| S.No |

Customer

/ Consultant |

Scope

of Supply |

Project |

| 1. |

Vam

Organic Chemicals Limited, Uttar Pradesh, India |

Design,

detailed Engineering, Supply, E & C of Drum

Level Control System |

10 TPH

FBC Boiler. Commissioned during July 1996 |

| 2. |

Mohan

Meakins Limited, Uttar Pradesh, India |

Design

detailed Engineering, Supply, E & C of Loop

Controller & PLC for BMS |

1

* 12 TPH, Gas Fired Boiler. Commissioned during

August 1997 |

| 3. |

Gemini

Distilleries Ltd., Karnataka, India |

Design,

detailed Engineering, Supply, E & C of Drum

Level Control System |

7

TPH FBC Boiler. Commissioned during November 1996 |

| 4. |

ACC

Bridgestone Limited, Madhya Pradesh, India |

Design,

detailed Engineering, Supply, E & C of C &

I package including PLC for BMS |

2

* 7 TPH Oil Fired Boiler. Commissioned during July

1998 |

| 5. |

Asian

Paints Limited, Tamil Nadu, India |

Design,

detailed Engineering, Supply, E & C of Variable

Speed Drive Panel |

1

* 7 TPH FBC Boiler. Commissioned during September

1997 |

| 6. |

ITC

Agro Tech Limited, Andhra Pradesh, India |

Design,

detailed Engineering, Supply, E & C of MAXCON

500 DCS |

1

* 20 TPH FBC Boiler. Commissioned during December

1994 |

| 7. |

Heinz

India Limited, Uttar Pradesh, India |

-do- |

1

* 12 TPH FBC Boiler. Commissioned during February

1995 |

| 8. |

India Glycols Limited,

Uttar Pradesh, India |

-do- |

1 * 20 TPH FBC Boiler.

Commissioned during December 1994 |

| 9. |

Gujarat

Heavy Chemicals Limited, Gujarat, India |

Design,

detailed Engineering, Supply of turnkey C &

I package with MAXCON 2000 Redundant DCS |

1

* 90 TPH FBC Boiler. Commissioned during August

1995 |

Case Studies

Project References – Power

Plant CCPP

20

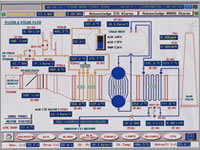

MW Combined Cycle Power Plant Automation at M/s.

NAGARJUNA ELECTRIC CO. LTD., AP, INDIA with

Siemens S5 135 U PLC SYSTEM for Boiler & S5 115

H Redundant PLC System networked to COROS Operator Stations

on SINEC H1. 20

MW Combined Cycle Power Plant Automation at M/s.

NAGARJUNA ELECTRIC CO. LTD., AP, INDIA with

Siemens S5 135 U PLC SYSTEM for Boiler & S5 115

H Redundant PLC System networked to COROS Operator Stations

on SINEC H1.

System Architecture: The Power plant is automated with Siemens non-redundant

S5 135 U PLC system in Boiler and Hot Redundant S5 115H

PLC System in Turbine. Both the PLC Systems are networked

in Dual Redundant Ethernet Communication Bus SINEC H1

with 3 Nos. Siemens COROS LSB Workstations. The PLC

System carries out Analog Controls, Data Acquisition

and Sequential Interlocks.

6

MW Captive Power Plant Automation at M/s. MADHYA

BHARAT PAPERS LTD., Chhatisgarh, INDIA with

Siemens S7 300 PLC SYSTEM for Boiler & S7 300 R

Redundant PLC System for Turbine networked to WIN CC

Operator Stations on MPI BUS 6

MW Captive Power Plant Automation at M/s. MADHYA

BHARAT PAPERS LTD., Chhatisgarh, INDIA with

Siemens S7 300 PLC SYSTEM for Boiler & S7 300 R

Redundant PLC System for Turbine networked to WIN CC

Operator Stations on MPI BUS

System

Architecture: The Power plant is automated

with Siemens non-redundant S7 300 PLC system with ET

200 M I/O Stations in Boiler area and the turbine area

is automated with Siemens S7 300 R Redundant PLC System

with Redundancy in Power Supply Level and Processor

Level supplied by Triveni. The Ash Handling System is

automated with S7 200 PLC System. All the PLC Systems

are networked on MPI Bus to Siemens WIN CC Workstation

for Analog Controls, Data Acquisition and Sequential

Interlocks.

Project

References – Power Plant CPP

6

MW Captive Power Plant Automation at M/s. MADHYA

BHARAT PAPERS LTD., Chhatisgarh,INDIA with

Siemens S7 300 PLC SYSTEM for Boiler & S7 300 R

Redundant PLC System for Turbine networked to WINCC

Operator Stations on MPI BUS. 6

MW Captive Power Plant Automation at M/s. MADHYA

BHARAT PAPERS LTD., Chhatisgarh,INDIA with

Siemens S7 300 PLC SYSTEM for Boiler & S7 300 R

Redundant PLC System for Turbine networked to WINCC

Operator Stations on MPI BUS.

Project References –

Power Plant Cogen

4

MW Cogeneration Plant Automation at M/s. SUN

PAPER MILL LTD, Tamilnadu, INDIA withSiemens

S7 300 PLC, SIPART Loop Controllers & ALLEN BRADELY

5/40 PLC networked to WIN CC SCADA System on MPI. 4

MW Cogeneration Plant Automation at M/s. SUN

PAPER MILL LTD, Tamilnadu, INDIA withSiemens

S7 300 PLC, SIPART Loop Controllers & ALLEN BRADELY

5/40 PLC networked to WIN CC SCADA System on MPI.

System Architecture: The Power plant is automated with Siemens automation

products involving SIPART Loop controllers

with RS 485 interface for Closed loop controls and Siemens

S7 300 PLC System for Data Acquisition and Sequential

Interlocks. The Loop Controllers on RS 485 bus and S7300

PLC on MPI Busarenetworked to the Siemens WIN CC Workstation.

In Turbine, AB make 5/04 PLC is supplied by Triveni

for automation of turbine. This PLC System is also interfaced

to WINCC Workstation on RS 485 Bus.

|

Project References

– Pulp & Paper

Stock

Preparation Plant Automation at M/s. WEST COAST PAPER MILL, Karnataka, INDIA withSiemens S7 400R Redundant PLC System with WIN CC

SCADA System on MPI. Stock

Preparation Plant Automation at M/s. WEST COAST PAPER MILL, Karnataka, INDIA withSiemens S7 400R Redundant PLC System with WIN CC

SCADA System on MPI.

System Architecture: Siemens S7 400 R Redundant PLC system with

ET 200 M I/O stations onRedundant PROFIBUS DP network

in distributed configuration networked with 2 Nos. Siemens

WIN CC workstation on MPI Bus for Data Acquisition,

Open loop controls, closed loop controls including Ratio

Control, Cascade Control, and Step Control including

sequential interlocking operation.

Special Achievement: For the first time in India, Stock Preparation

plant is automated with PLC System at economical cost

instead of conventional DCS.

Stock

Preparation Plant Automation at M/s. WEST COAST PAPER MILL, Karnataka, INDIA withSiemens S7 400 R Redundant PLC System with WIN CC

SCADA System on MPI. Stock

Preparation Plant Automation at M/s. WEST COAST PAPER MILL, Karnataka, INDIA withSiemens S7 400 R Redundant PLC System with WIN CC

SCADA System on MPI.

Color Kitchen Automation at M/s. JK PAPERS LTD, Orissa, INDIA with

Siemens S5 135 U PLC Systems to WONDERWARE IN TOUCH

SCADA package on PROFIBUS.

System

Architecture: The color kitchen is automated

with 3 Nos. of Siemens S5135 U PLC’s with ET 100U

I/O stations. The S5 135 U PLC is networked on PROFIBUS

with Wonderware INTOUCHworkstation for Data Acquistion,

Sequential Interlocks and Analog controls. The S5 135

U PLC with ET 100 U modules were procured by JKPM along

with the second hand color kitchen from Switzerland.

Colour kitchen Automation involves areas like Clay Mixer,

Starch Mixer and Colour Mixer. System

Architecture: The color kitchen is automated

with 3 Nos. of Siemens S5135 U PLC’s with ET 100U

I/O stations. The S5 135 U PLC is networked on PROFIBUS

with Wonderware INTOUCHworkstation for Data Acquistion,

Sequential Interlocks and Analog controls. The S5 135

U PLC with ET 100 U modules were procured by JKPM along

with the second hand color kitchen from Switzerland.

Colour kitchen Automation involves areas like Clay Mixer,

Starch Mixer and Colour Mixer.

Color

Kitchen Automation at M/s. JK PAPERS LTD, Orissa, INDIA with Siemens S5 135 U PLC Systems to WONDERWARE IN TOUCH

SCADA package on PROFIBUS. Color

Kitchen Automation at M/s. JK PAPERS LTD, Orissa, INDIA with Siemens S5 135 U PLC Systems to WONDERWARE IN TOUCH

SCADA package on PROFIBUS.

Project References

– Process Application

Gypboard

Plant Automation at M/s. INDIA GYPSUM LTD, Maharashtra,

INDIA with SiemensS7 400 PLC System networked to WIN

CC SCADA package on PROFIBUS. Gypboard

Plant Automation at M/s. INDIA GYPSUM LTD, Maharashtra,

INDIA with SiemensS7 400 PLC System networked to WIN

CC SCADA package on PROFIBUS.

System Architecture: The gypsum board plant

is automated with Siemens S7 400 PLC networked with

ET 200 M I/Ostations on PROFIBUS. The PLC system is

networked with WIN CC workstations on PROFIBUS on Data

Acquisition, Sequential Interlocks and Analog controls. System Architecture: The gypsum board plant

is automated with Siemens S7 400 PLC networked with

ET 200 M I/Ostations on PROFIBUS. The PLC system is

networked with WIN CC workstations on PROFIBUS on Data

Acquisition, Sequential Interlocks and Analog controls.

Gypboard Plant Automation at M/s. INDIA GYPSUM

LTD,, Maharashtra, INDIA with Siemens S7 400

PLC System networked to WIN CC SCADA package on PROFIBUS. Gypboard Plant Automation at M/s. INDIA GYPSUM

LTD,, Maharashtra, INDIA with Siemens S7 400

PLC System networked to WIN CC SCADA package on PROFIBUS.

Raw

Material Preparation Plant Automation at M/s.

EVEREST INDUSTRIES LTD,, Tamil Nadu, INDIA with Siemens S7 300 PLC System & SIWAREX Weighing

modules networked to WIN CC SCADA package on MPI. Raw

Material Preparation Plant Automation at M/s.

EVEREST INDUSTRIES LTD,, Tamil Nadu, INDIA with Siemens S7 300 PLC System & SIWAREX Weighing

modules networked to WIN CC SCADA package on MPI.

System Architecture: The Raw Material

preparation plant for asbestos manufacturing unit is

automated with Siemens S7 300 PLC and SIWAREX weighing

modules, a complete batching system with static hopper

weighing system. The PLC networked with ET 100 M I/O

stations on PROFIBUS and with WIN CC workstation on

MPI for Data Acquisition, Sequential Interlocks and

Analog controls.

Raw

Material Preparation Plant Automation at M/s.

EVEREST INDUSTRIES LTD,

Tamil Nadu, INDIA with Siemens S7 300 PLC System & SIWAREX Weighing

modules networked to WIN CC SCADA package on MPI. Raw

Material Preparation Plant Automation at M/s.

EVEREST INDUSTRIES LTD,

Tamil Nadu, INDIA with Siemens S7 300 PLC System & SIWAREX Weighing

modules networked to WIN CC SCADA package on MPI.

|